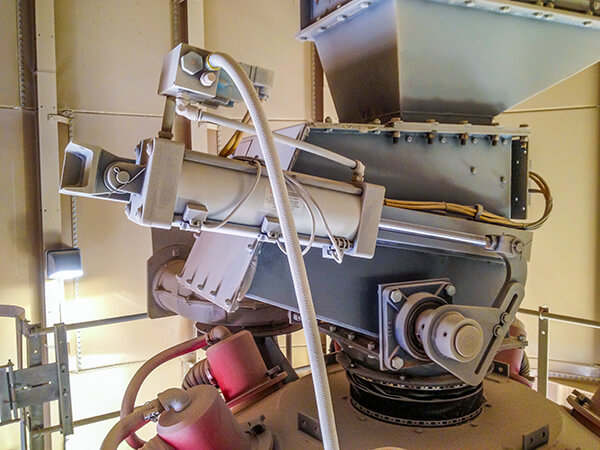

Shut off material flow from outlets of silos, bins, and other discharge points.

Sizes from 6” to 36” square.

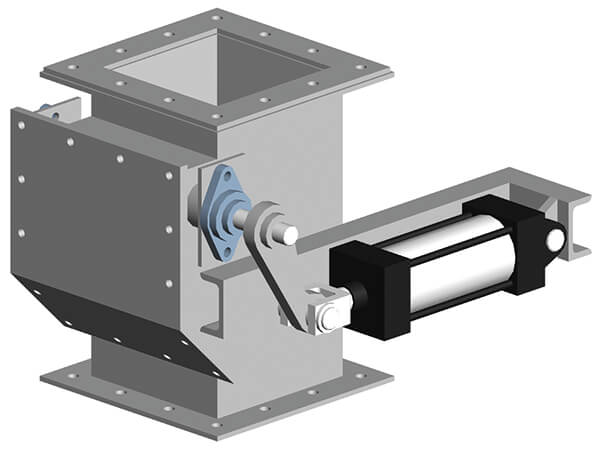

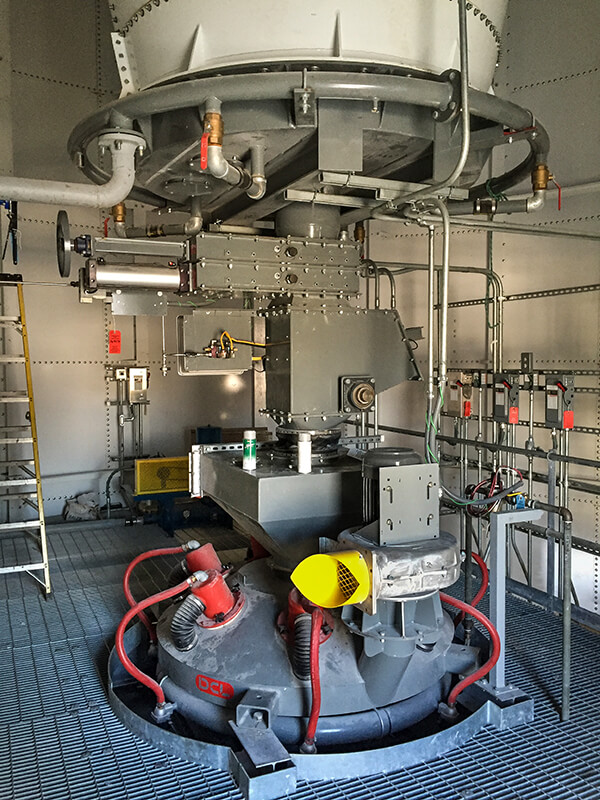

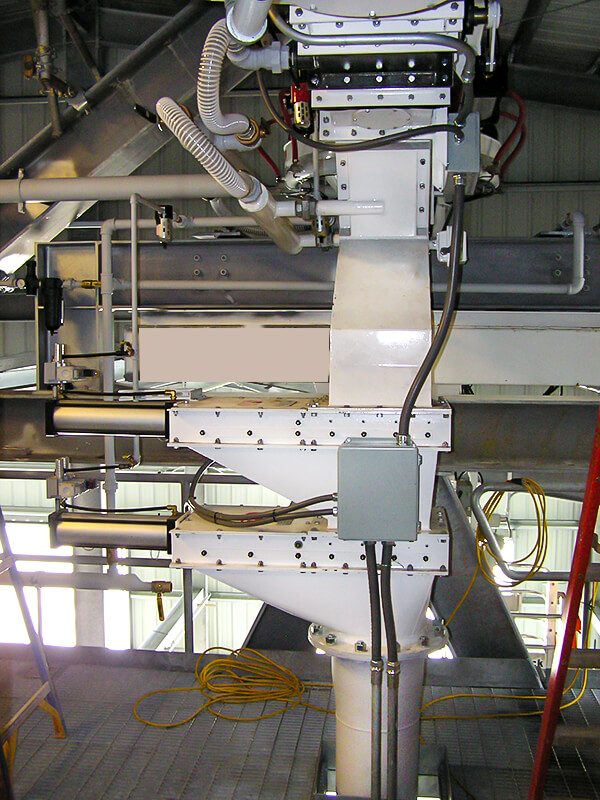

Slide gate valves are designed to shut off the flow of product from outlets of dry bulk storage bins, silos, conveyors and other discharge points. DCL’s slide gate valve frames are constructed from heavy duty 3/16 inch steel with a hardened Blanchard-ground blade which rides on cam rollers or solid guides.

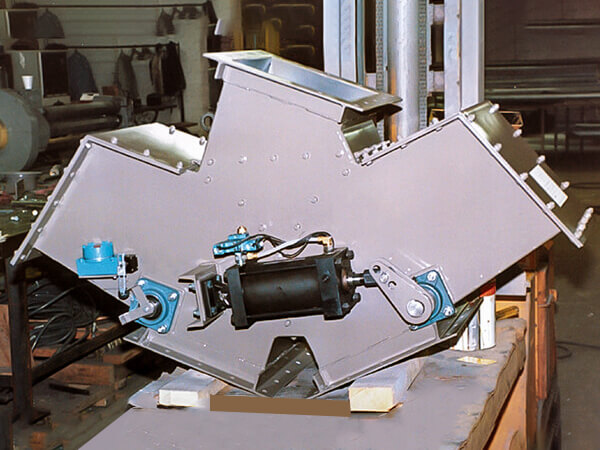

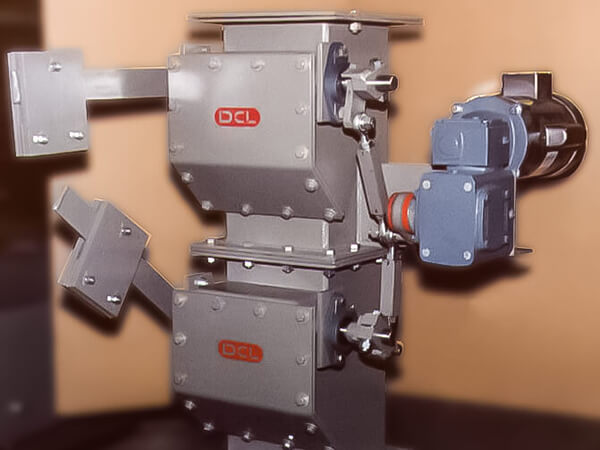

You can actuate slide gate valves in a number of ways: pneumatically for fast action, hydraulically for power, electrically for precise positioning and manually for maintenance and flow control.

Blade seals are selected according to the material being handled and are available to suit any application. A molded urethane inlet liner provides an ideal blade seal if you handle granular products. Additional frame seals are available and should be used if you handle fine dusty material. We also make adjustable seals, which prolong lifespan by reducing the need for seal replacement. These are adjusted from outside the valve frame, a feature unique to the industry.

All DCL slide gate valves are equipped with a dust-tight transition unless they are mounted directly above another valve. This prolongs seal life by relieving product before it packs in the retracted position.

We offer a large selection of slide gate valves from 6 inches [152 mm] square up to 36 inches [914 mm] square. Slide gates are also available in sizes larger than 36 inches [914 mm], rectangular and special configurations including dual opposing blade and dewatering designs on a custom build basis.

A choice of construction materials allows you to effectively handle all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.