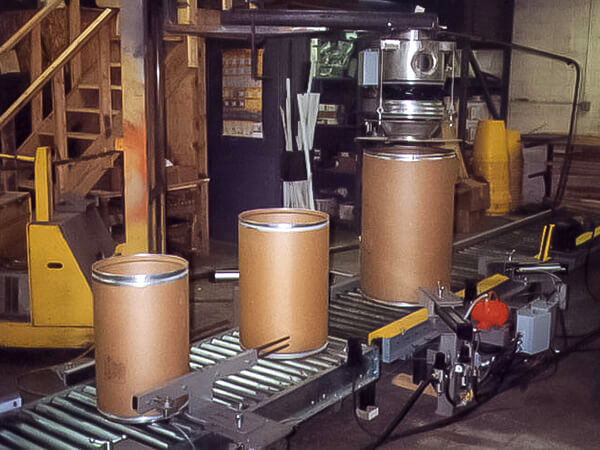

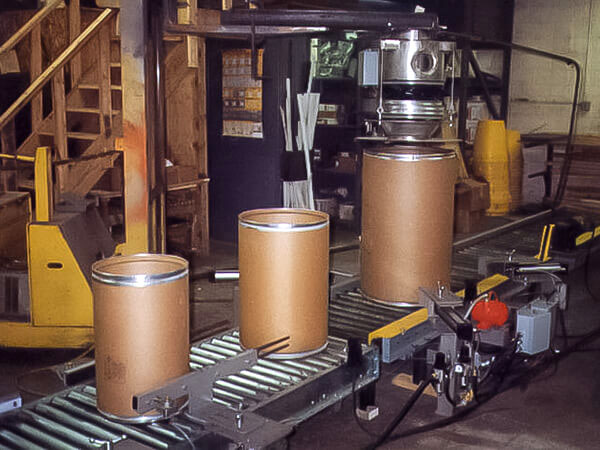

BAG FILLING STATION

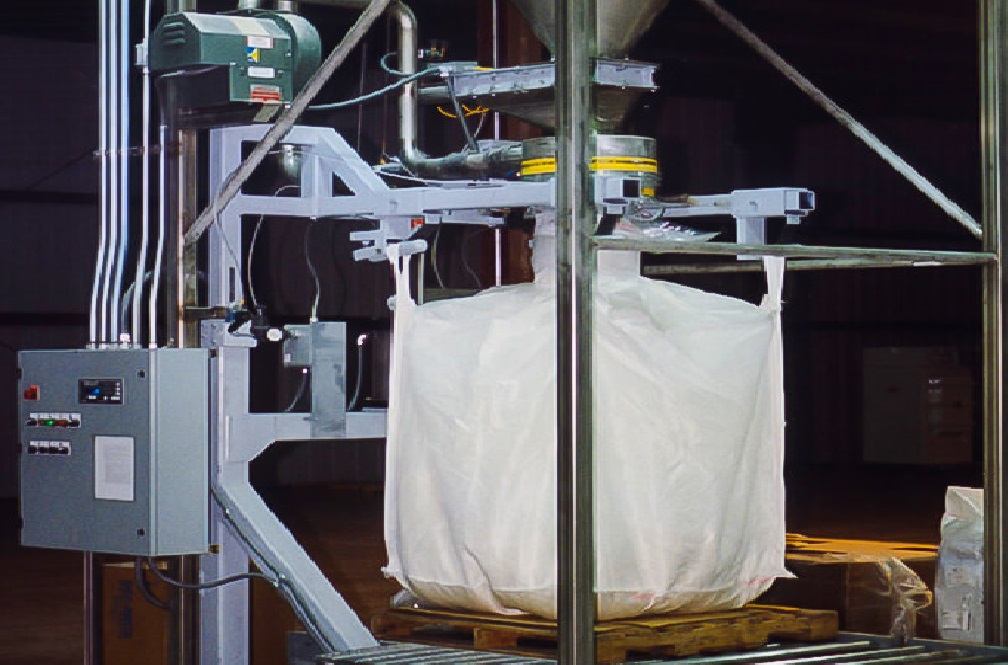

DCL offers a wide variety of bag fill stations that can handle bags from 25 to 60 cubic square feet.

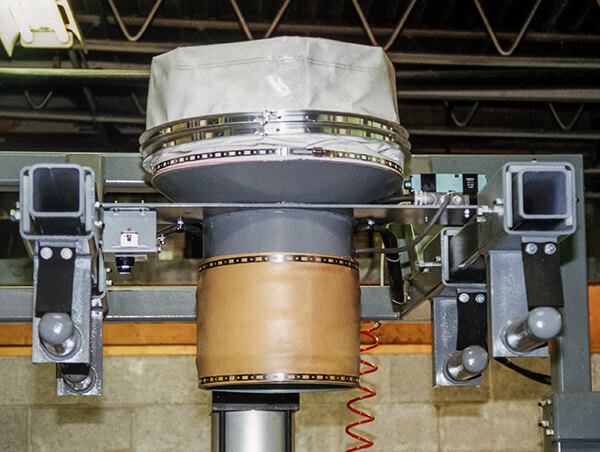

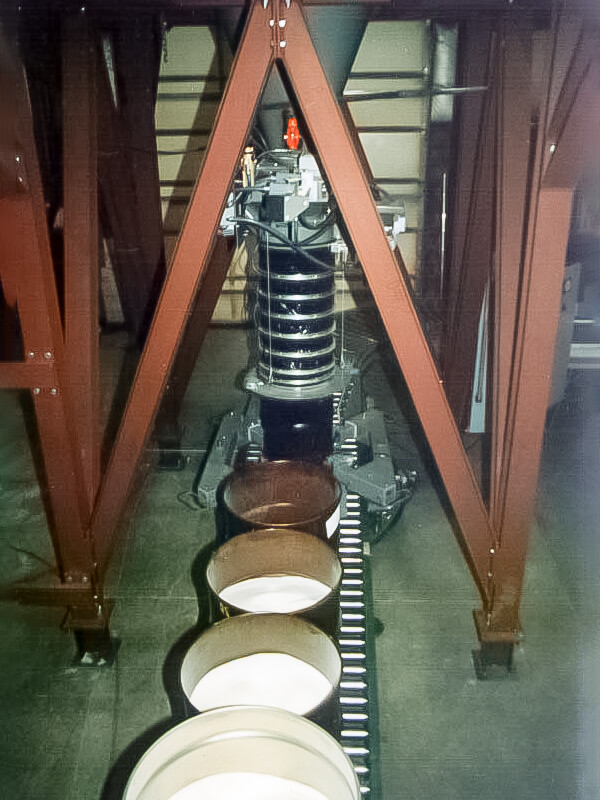

DCL’s dust-free bulk bag filling stations are provided in configurations tailored for your specific bagging application. They can be designed to accommodate a full range of bag sizes. The systems use high-accuracy scales with manual sequence or PLC controls. The bag fill station comes in two typical designs, a two-post and four-post.

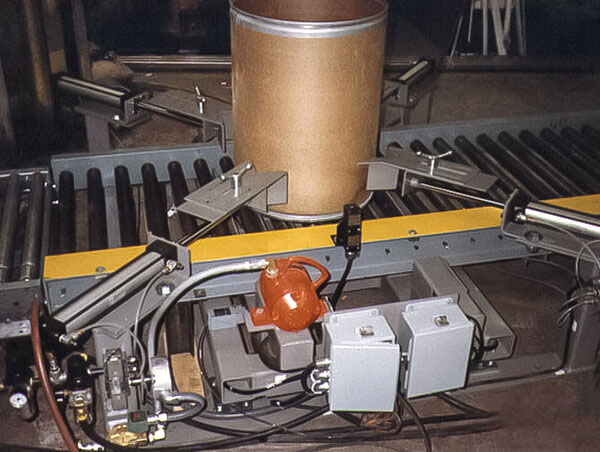

A wide variety of options offer you manual or fully automatic operation. Bag filling options include:

- Automatic strap release

- Powered and gravity

- Roller conveyors

- Empty pallet dispenser

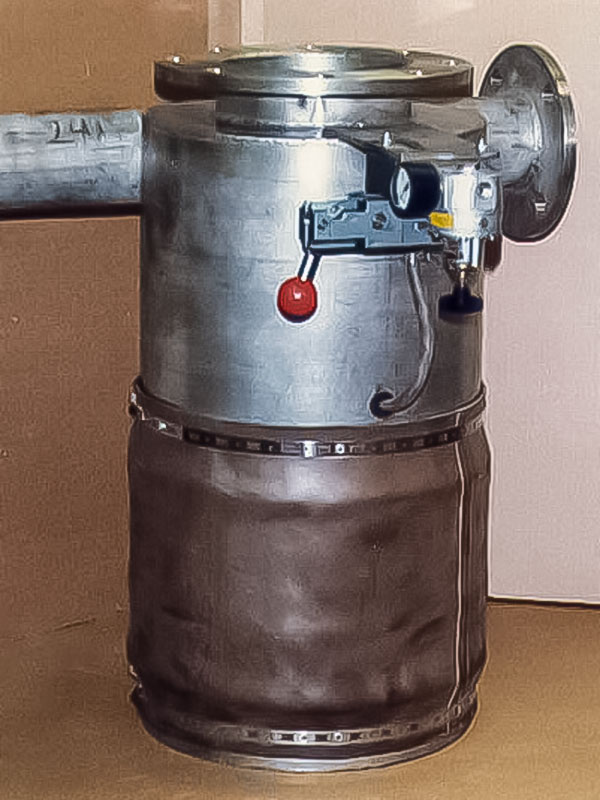

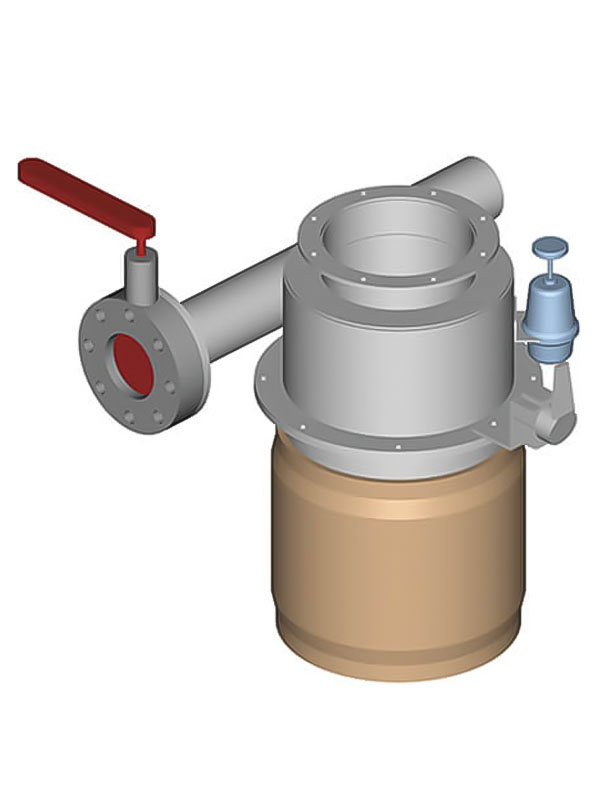

- Full and dribble feed product flow control valve

- Drum and box filling adapters with

- Simultaneous weighing and densifying and integral filters

A choice of construction materials allows you to effectively bag all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.