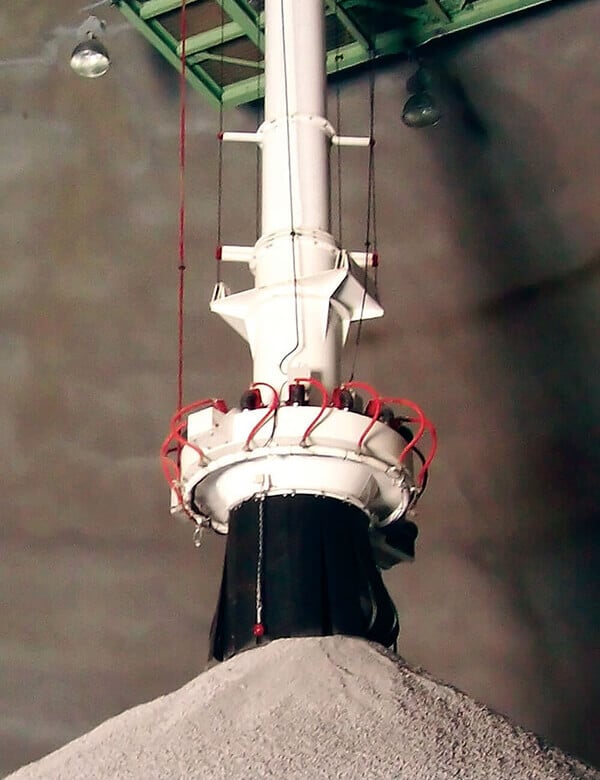

Filters dust from a loading spout and discharges particles back into material flow.

Sizes up to 660 sq. ft. of filter media with up to 5,000 CFM air withdrawal.

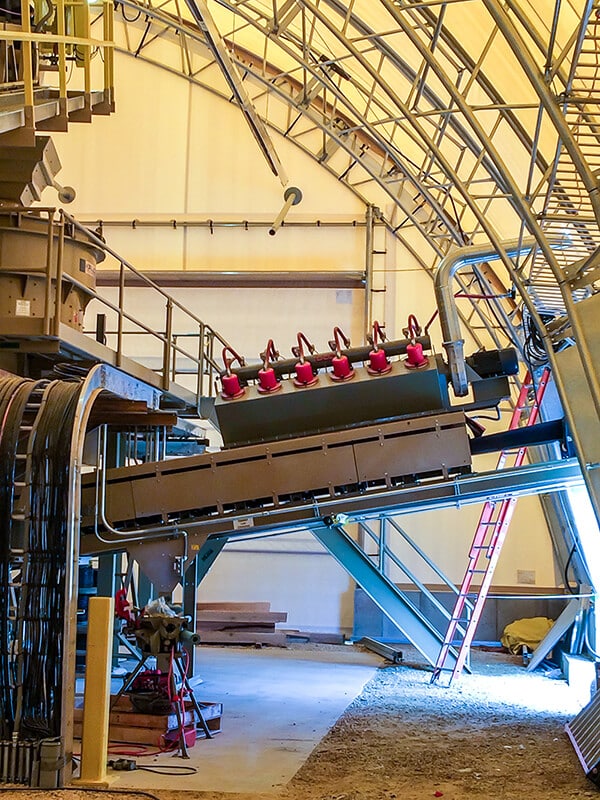

The VMV and VML Ventilation Modules are an excellent choice for dust control when used directly at the source: conveyor head chutes, ventilation of enclosed conveyors, screeners, mixers, silos and batching bins.

The specially designed pleated filter elements are sized to be easily handled and are replaced without tools.All dust collected by the VMV and VML is deposited back to the material being handled. This makes the DCL

Ventilation Module an ideal cost-effective package compared to a free-standing dust collector that would require ductwork, a discharge air lock and a means to convey dust back into the system.

The exhaust fan is directly mounted to the assembly, eliminating the need for a remote fan placement. This unique design provides internal velocities lower than what you’d expect in conventional

designs. This gives you less load on your filtration media. The filter elements are automatically cleaned during operation with a conventional 80-100 PSI pulse jet system. The unit can also be

provided with a final clean feature. When activated at the end of each loading cycle, it fully cleans all elements, eliminating residuals.

Filter media is available to accommodate most applications. Pleated design, spun-bonded media features a smooth surface finish with exceptional dust cake release. The filter surface is calendared

and compacted to resist penetration by collected particulate. This results in better cleaning efficiency and faster return to operating airflow after the cleaning cycle than traditional media.

DCL offers a large selection of ventilation modules from 85 to 750 square feet of filter media. Exhaust fans can be sized up to 6000 CFM.

A choice of construction materials allows you to effectively handle all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications. You

can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.